Brake Service & Repairs

Inspections start at $39.97

Anti-Lock Brakes (ABS)

Description:

Today, virtually all cars have ABS as standard equipment or an option. The typical ABS system includes wheel-speed sensors, an electronic control unit, and a hydraulic control unit.

When you apply the brake pedal, the electronic control unit monitors and compares the signals from the wheel-speed sensors. Suppose the electronic control unit senses rapid deceleration (impending lock-up) at a given wheel. In that case, the electronic control unit commands the hydraulic control unit to reduce hydraulic pressure on that wheel.

This type of pressure limiting is similar to pumping the brake pedal, only much faster. Some pick-up trucks and cargo vans have rear-wheel-only ABS to handle different braking needs under various loading conditions. This type of ABS system controls only the rear wheels and limits pressure when either is about to lock up.

Purpose:

The purpose of ABS is to maintain directional control of your vehicle when emergency stops are needed or when there are adverse road conditions. Directional control helps you avoid accidents, especially when the roads are wet.

Pumping the brake pedal is unnecessary if your vehicle has ABS. This is because your car will automatically “pump” them. Instead, if you apply firm and continuous pressure to the brake pedal, the ABS operation is automatically activated.

Once it is activated, a pulsing sensation may occur on the brake pedal. This indicates the ABS operation is no longer necessary. This will revert the braking system to a conventional hydraulic function without intervention from the ABS system.

Maintenance Tips/Suggestions:

When turning the ignition switch to the on position, the amber BRAKE, ANTILOCK, or ABS light on the instrument panel should glow temporarily and then turn off. If the light stays on, flashes, or comes on while driving, it indicates a fault in the ABS.

Have your car’s ABS system inspected immediately by D & R Intensive Car Care to determine the problem’s source and decide whether brake repair is necessary. Your owner’s manual may specify periodic flushing and filling of the brake hydraulic system, which you should never overlook. This service is best for professional technicians, as many cars with ABS have specialized brake-bleeding procedures.

Braking systems with ABS can also generate extremely high hydraulic pressures, which can be dangerous. Once again, consult D & R Intensive Car Care if your car needs ABS or hydraulic system service.

Brake Hydraulics/Brake Fluid

Description:

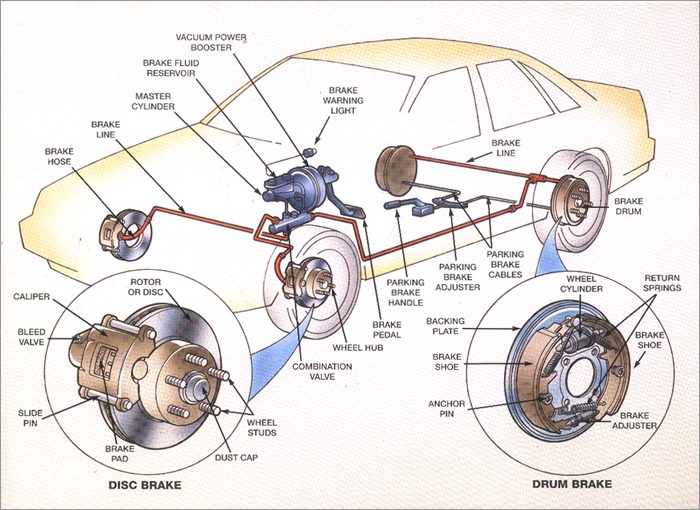

The brake hydraulic system comprises the master cylinder, disc brake calipers (disc brakes), wheel cylinders (drum brakes), hydraulic lines and hoses, and combination/proportioning valves.

When you push on the brake pedal, the force of your leg generates hydraulic pressure in the master cylinder, which then flows through the hydraulic lines and hoses into the wheel cylinders and calipers. The hydraulic force applies pressure through the wheel calipers and cylinders, forcing the shoes against the drums (drum brakes) and the pads against the rotors (disc brakes).

In the early 1960s, cars began using split-hydraulic systems and tandem master cylinders. Essentially, this divided the hydraulic system into two separate systems (front and back), ensuring proper hydraulic and braking on one side of the system in case a leak developed on the other side. In the 1980s, some carmakers began to use diagonally-split systems, which took safety a step further. Instead of splitting the system into front and rear, the system was now hydraulically divided into left-rear/right-front and right-rear/left-front.

Maintaining one front and one rear brake results in more balanced braking when the system develops a leak. By law, all of today’s cars require a hydraulically-split system

Brake fluid is a specially formulated liquid used in the brake hydraulic system. Brake fluid must meet one of three U.S. Department of Transportation (DOT) specifications. DOT3 and DOT4 are glycol-based fluids that absorb water. DOT5 is a silicone-based fluid and does not absorb moisture. Most cars use DOT3 fluid from the factory.

Purpose:

Since you cannot compress liquids, brake fluid transmits force to various parts of the braking system when you step on the brake pedal. Brake fluid must have a high boiling point because of the heat generated during braking and must not freeze during cold temperatures.

Maintenance Tips/Suggestions:

Check on the brake fluid level in the master cylinder reservoir regularly. D & R Car Care checks your brake fluid at every oil change. Most cars use semi-transparent reservoirs with level markings to make fluid monitoring easy. If you need to add fluid, use only the type of fluid recommended in your car’s owner’s manual.

Do not leave the cover off the master cylinder any longer than necessary, as DOT3 and DOT4 brake fluids attract water. Use extreme care when handling DOT3 and DOT4 fluid, as it quickly destroys paint if spilled. On cars with disc brakes, it’s normal for the fluid level to drop as the brakes wear gradually.

This fluid fills up the space left by the disc brake caliper pistons as they move outward with brake wear. However, if you find that brake fluid needs to be added frequently, there may be a leak in the hydraulic system. If you are experiencing this, have the system inspected by D & R Car Care as soon as possible.

Your owner’s manual may specify periodic flushing and filling of the brake hydraulic system, which should not be overlooked. Regular flushing of your vehicle’s brake fluid system will remove water and contaminants from the system that may cause corrosion and premature system failure. This service is best left to D & R Car Care, as many cars with ABS have specialized brake-bleeding procedures.

Braking systems with ABS can also generate extremely high hydraulic pressures, which can be dangerous. Once again, consult D & R Car Care if your car needs ABS or hydraulic system service.

Brake Hardware

Description:

Brake hardware generally refers to the supporting hardware for disc and drum brakes. Hardware related to disc brakes usually includes anti-rattle springs, pad-retaining springs, silencing shims, caliper pins, support keys, return springs, and retaining screws. Typical drum brake hardware includes return springs, hold-down springs, tension springs, and a star wheel adjuster. It’s important to note that the exact hardware configuration and names of the hardware vary considerably with different makes and models of cars.

Purpose:

Brake hardware is used to retain brake parts in specific locations and can also be used to return parts to certain positions when hydraulic pressure is released. Certain types of brake hardware can also be used to silence disc brakes.

Maintenance Tips/Suggestions:

Symptoms of brake hardware problems may include dragging brakes, squealing while braking, grinding brakes, a low brake pedal, or pulling when braking.

If your car exhibits any of these symptoms, have it checked out by D & R Car Care as soon as possible. We will replace your brake hardware whenever we service your brakes. Having the hardware replaced during brake service is the best investment you can make to ensure safe braking and a longer life for your new brakes.

Brake Pads and Brake Rotors/Brake Shoes and Brake Drums

Description:

Brake pads and brake shoes are the friction linings pressed by the brake caliper to the brake rotor (disk brakes) or by the wheel cylinder to the brake drum (drum brakes) to provide the friction required to stop your vehicle. Today’s friction linings may contain semi-metallic compounds, non-asbestos organic compounds, ceramics, etc.

Brake drums and rotors are the spinning members of the braking system that come in contact with the lining material from the brake shoes and brake pads. Brake drums are typically cast iron, and brake rotors may be made of cast iron or a composite of cast iron and a stamped steel center section.

Purpose:

Brake pads and brake shoes are the wearable friction elements of the braking system. They should provide reliable and quiet braking for many miles when properly installed.

Brake drums and brake rotors provide the mating surface for brake shoes and pads. Because of the heat generated from all the friction, a brake drum or brake rotor must remain stable even when subjected to the high temperatures of repeated braking.

Maintenance Tips/Suggestions:

Have your vehicle’s brakes inspected annually by D & R Car Care to ensure everything’s in order. It’s always best to plan for brake work by knowing the brake condition as your car ages. Brakes are a standard wear component for any car, so sooner or later, they will need replacement. Planning can also save you money because the brakes won’t get to the “metal-to-metal” point, which usually means an expensive brake rotor or brake drum replacement.

Symptoms of problems with your brakes may include dragging brakes, squealing brakes, a pulsating brake pedal (with ABS not functioning), grinding brakes, a low brake pedal, or pulling or shaking when braking. If your car exhibits any of these symptoms, have it checked out by D & R Car Care as soon as possible.

Brake Vacuum Booster

Description:

The brake vacuum booster on the driver’s side of the car towards the back of the engine compartment is the heart of a “power brake” system. The master cylinder mounts to the front of the brake booster.

Purpose:

The brake booster uses the differential of engine vacuum (negative pressure) and atmospheric pressure (positive pressure) to multiply force from the driver’s leg. This applies increased force to the pushrod of the master cylinder, generating more pressure from the master cylinder than from the use of the driver’s leg alone.

Maintenance Tips/Suggestions:

Brake boosters are generally very reliable and require no maintenance. Some boosters have a small filter in the vacuum line supplying the booster. Regular replacement of this will ensure a consistent vacuum flow to the booster. Routine inspection will ensure that its vacuum connection and hose are sound and that the connection grommet seals tightly around the vacuum connection.

Symptoms of brake booster problems include excessive brake pedal effort, a rough running engine, excessive idle speed, or a whooshing or hissing noise. Have the symptoms checked by D & R Car Care to pinpoint the cause.

Hydraulic and Parking Brake Warning Light

Description:

The hydraulic and parking brake warning light is located on the instrument panel. The warning light is usually red and labeled BRAKE. The light glows with the ignition switch in the on position.

Purpose:

The hydraulic warning light glows when a loss of pressure is detected in the hydraulic system. This light will alert the driver in some cars that the brake fluid level is low.

The parking brake warning light notifies the driver that the parking brake is engaged. This warning light reduces the chances of driving off with the parking brake engaged, causing premature rear brake wear.

Maintenance Tips/Suggestions:

If your vehicle’s amber BRAKE warning light comes on, check your vehicle’s owner’s manual to find out its meaning. Unlike some warning lights, the BRAKE warning light does not have standard meanings; it can signify multiple meanings.

For example, the same light will show that the parking brake is engaged and when the fluid in the master cylinder is low. When in doubt, check the condition immediately by D & R Car Care. A loss of hydraulic pressure can affect brake operation, making your vehicle unsafe.

Use your parking brake regularly. Not using the parking brake for an extended period of time and then activating it may cause cables and other parts to seize because of corrosion. If the BRAKE light stays on after you’ve released the parking brake, it may indicate a hydraulic system problem because the same light can indicate multiple malfunctions. There’s also the possibility that the parking brake cable or switch may be sticking or is out of adjustment.

Schedule an appointment with D & R Car Care to pinpoint the cause of the warning lights. Our technicians will identify, diagnose, and perform brake services and repairs on any problems found.

8 Potential Brake Problems That Indicate You Need Repairs

Here are eight signs to look out for when driving that could mean it’s time to schedule your brake service.

Brake Warning Light On

It’s the simplest problem, but one that many people may overlook. If the brake warning lights turn on on your dash, then it could be an indication that you need to have your brakes inspected. This could mean that your vehicle needs a simple brake service, or there could be may be a bigger problem lurking beneath the surface.

It may also be an issue with the electronic control unit, and on some vehicles, it could be an indication you have your parking brake on. First check your parking brake, and if that’s not the issues, then you’ll want to be sure to call a mechanic and have your brakes checked.

Soft Brakes/Fluid Leak

Resistance is key for braking. If you find that you push down on the brake pedal and it sinks straight to the floor, you need to take your car to a mechanic immediately. If you’re near the Statesboro, GA area, call us and we will be able to help you. Lack of resistance in your brakes could be a sign that your brake system is losing pressure or that there is moisture inside the braking system. It could be an indication the master cylinder is leaking brake fluid and will need to be repaired. Lack of resistance in your brakes could result in a horrific accident if not resolved immediately.

Car Pulls To One Side

If your car pulls to one side when you brake, then this could indicate a number of issues that need immediate attention. A defective caliper is one issue that can go unnoticed until it’s too late and a repair has to turn into a replacement. Having your car serviced and your brake calipers carefully examined and the slide pins lubricated can avoid them becoming defective.

Another issue might be a broken brake hose causing a leak. As braking systems work together, you’ll find that a leak may only affect one side of the car and therefore cause a slight swerve when you brake.

Shaking When Braking

If you notice shaking in your steering wheel, this could indicate a problem with your front braking system. If you notice shaking throughout your entire car, it could an indication that there’s a problem with your back braking system. It might also be that your brake rotors are uneven.

Noise When Braking

Squealing, squeaking, grinding sounds. All three of those noises are things to be cautious of when you brake. It could be something as simple as something lodged within the brakes. It could also be an indication of worn brake pads.

The best solution is to take the car in for inspection so they can determine what the problem is. If it’s discovered that it’s a case of brake pad wear, then get them replaced soon before metal-on-metal contact occurs. It’ll be a much more costly process otherwise.

Burning Smell

A burning smell when you brake could be an indication that your brakes or caliper are overheating. You should pull over to the side and give them a chance to cool off. If there is smoke, the problem may be a stuck brake caliper. Either way, it would be wise to take the care to be looked over.

Pulsing Brake

If you can feel your brakes shaking when you press down on them, this could be an indication there’s a problem with your brake rotors. If they warp from use over time, this could result in you needing to completely replace your brake rotors. Avoid warping by having your brake rotors resurfaced by a skilled technician.

Brake Failure

It can seem self-explanatory, but even a partial brake failure should never be taken for granted. If you find that you apply pressure to the brakes and they do not slow down or do not slow down at a quick rate, immediately stop driving the car and call a tow truck to take it in to be checked. This issue could result in serious injury or even death for both you and anyone else on the road.

Keeping Your Brakes in Good Condition

While a skilled car technician can tell you the estimated life of your brakes, the biggest factor in any situation is your own driving habits. These simple tips can prevent you from needing to take your car in early, or risk a costly repair.

- Avoid Stop & Go Driving

- No Tailgating

- Avoid Aggressive Driving

- Clean Out Your Car

- Routine Maintenance & Brake Inspection

For more information on brake issues, or to schedule your next vehicle maintenance visit in Statesboro, GA, call D & R Car Care today. Our ASE-certified technicians are equipped to handle all major and minor auto repair services on domestic and foreign vehicles. We are conveniently located on South Main St in Statesboro, across from Georgia Southern University.